How to effectively deal with drilling waste?KOSUN gives you the answer!

Drilling waste/mud is one of the major sources of pollution in the oil and gas industry. Due to engineering requirements, drilling mud is often mixed with substances such as oil, water, and organic clays. In recent years, the use of oil-based mud, water-based mud, and composite-based mud has increased, leading to escalating costs and environmental pollution issues.

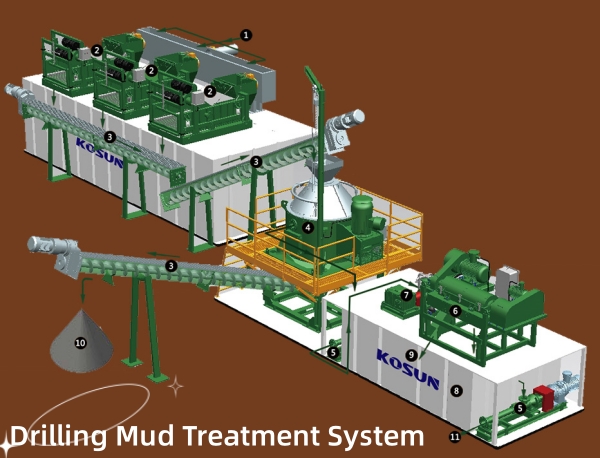

The emergence of mud treatment systems has successfully addressed the challenge of inefficient and environmentally friendly treatment of drilling waste. The main processing process of Xi’an KOSUN’s drilling waste treatment system refers to the harmless treatment of drilling waste from the wellhead before landing. The waste mud in the waste mud pool can also be diluted and then classified and utilized for treatment, realizing the mobilization of drilling environmental protection devices. Mud that has been effectively treated can be reused, reducing frictional resistance, lowering accident rates, and improving wellbore quality.

Drilling cuttings treatment method:

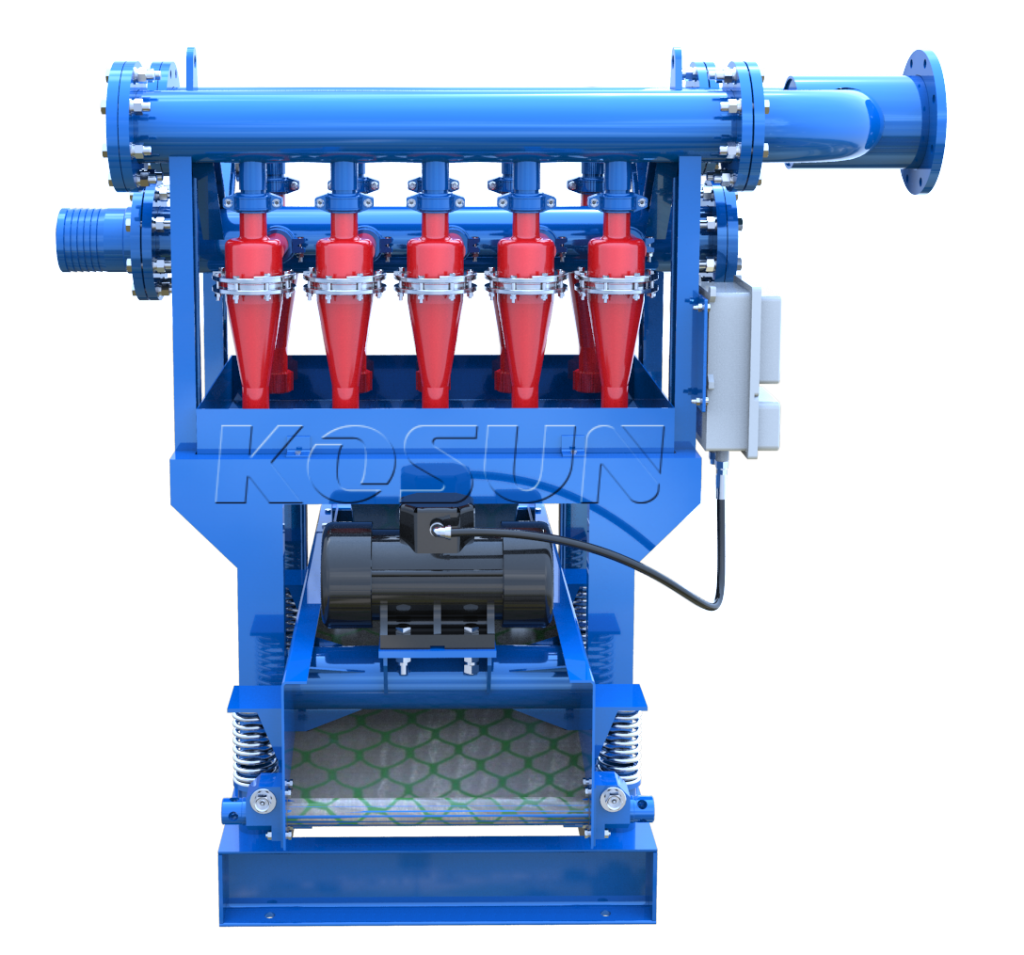

Different from traditional methods, the mud system transforms the treatment of waste mud from “end-of-pipe treatment” to “whole-process control”. The waste mud is diluted, coagulated, and separated into cuttings, mud cakes, and water. Solid substances in the mud are treated through washing, coagulation separation, and chemical reaction to meet discharge standards. Harmful substances and chloride ions in the mud are dissolved into the water, which is then dehydrated into mud cakes by vacuum adsorption or squeezing. Meanwhile, the centrifugally separated wastewater undergoes concentration treatment through flotation sedimentation, filtration systems, and reverse osmosis systems. The treated wastewater meeting standards can be reused for drilling circulation.

Steps for drilling mud waste treatment:

Waste materials separated from drilling waste, such as cuttings, can be purified, dried, and recycled as concrete materials.

The mud water produced from washing cuttings can be chemically treated, destabilized, coagulated, and separated into mud cakes, which can be mixed with clay or shale in proportion for brick making.

The separated filtrate undergoes pretreatment processes such as destabilization, coagulation, flotation, oxidation, and adsorption filtration to remove major pollutants. It can be used for oilfield reinjection, safe strata reinjection, or discharged up to standards. After treatment by the sewage treatment system, wastewater can achieve standard discharge.

Considerations for drilling mud waste treatment:

Xi’an KOSUN’s drilling waste treatment system is the only environmentally friendly device in China that truly achieves harmless and green treatment of drilling waste mud, combining the most advanced mud purification and drying treatment technology at home and abroad, and after three years of research and multiple improvements and upgrades. The use of the mud treatment system eliminates the need to transport solid waste from the wellsite for centralized treatment, saving transportation costs and processing space, and making environmental protection efforts more effective.