KOSUN is a set of product research and development, production and sales, engineering services as one of the national high-tech enterprises. KOSUN has long been committed to the research and development and manufacturing of all kinds of screening equipment and centrifuges and other separation machinery products. The integrated technology of slurry separation system is in the leading level of the industry.

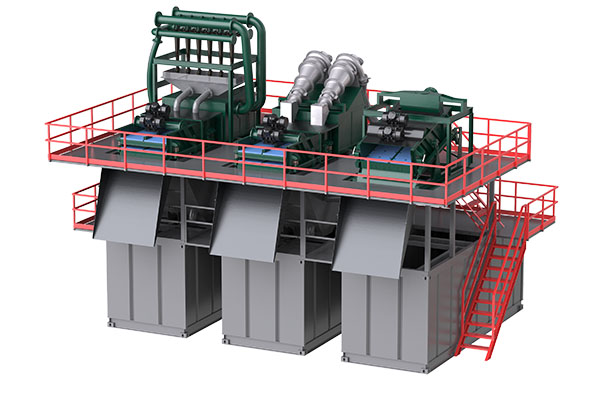

The series of Slurry separation system with 0-1000m3/h processing capacity designed and manufactured by KOSUN are widely used in infrastructure construction, municipal sewage treatment, tailings recovery and dehydration treatment, industrial wastewater, petroleum, chemical and other industries. At the same time, according to the needs of users, we can provide customers with the best separation effect of environmental technology and equipment. At present, we have provided customers in more than 60 countries and regions with a variety of separation mechanical products and sludge dewatering integrated solutions.

In the mud laboratory of KOSUN, the materials to be treated were studied through various tests of mud breaking, flocculation and separation and the analysis of chemical composition of all kinds of mud. Finally, the successful process route verified by the separation test is determined, and then the supporting equipment is extended to the field application of mud-water separation.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com