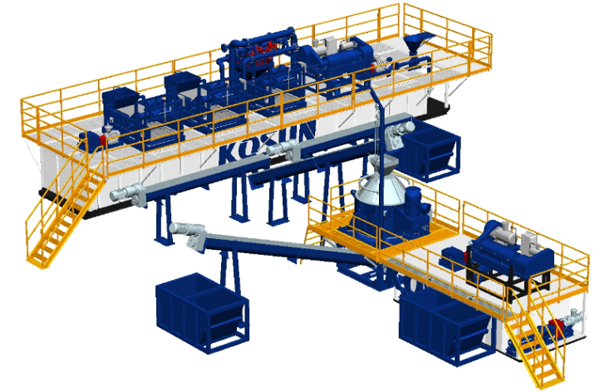

Features & Benefits of KOSUN Drilling mud waste treatment system:

-Efficient solid-liquid separation. Liquid content of treated solids is up to national and industrial standards.

-Effective recovery of treated liquid for recycling in drilling solids control system.

-Greatly reduce solid discharge volume, drilling fluid cost and waste management cost.

-Meet field operation requirements on zero discharge of drilling waste.

-Rotate at a high speed of 900RPM to generate a centrifugal force of 430G and effectively separate liquid from cuttings.

-Flights coated with wear-resistant material and metal screens for longer service life.

-Intelligent pulse jet control system effectively prevents screen blockage.

-Separate oil circuit lubricating and cooling system for simple and reliable operation.

-Integrated programmable control system for safe and convenient operation.

-Feed/discharge ports can be equipped with screw conveyors to facilitate drilling cuttings conveying and continuous equipment operation.

Three Drilling mud waste treatment solutions:

Solution 1: The system mainly consists of shale shaker, decanter centrifuge and tanks, used for the water-base drilling mud and drilling waste treatment. The drilling mud after treatment can be reused, but the moisture content of treated solid phase is relatively high.

Solution 2: The system mainly consists of vertical cutting dryer, decanter centrifuge and tanks, used for the water-base / oil-base drilling mud and drilling waste treatment. The moisture content and oil content of treated solid phase is lower.

Solution 3: The system mainly consists of filter press, chemical-adding unit and tanks, used for the water-base drilling mud and drilling waste treatment. The moisture content of treated solid phase is lower, but the working process is relatively complex and the equipment floor area is big.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com