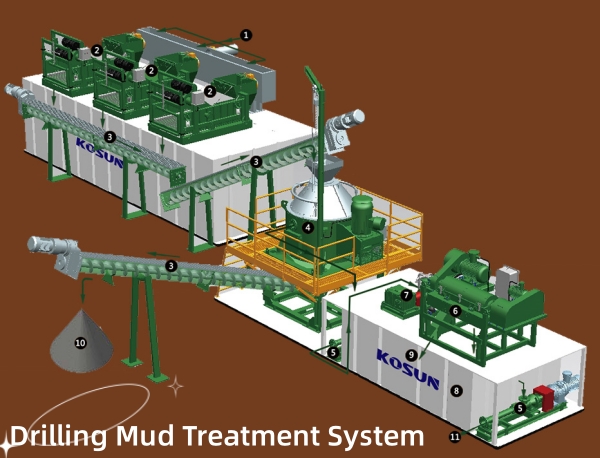

Drilling waste disposal is an important aspect of the drilling industry, and finding the right drilling waste disposal equipment is crucial for companies working in this industry. Xi’an KOSUN Environmental Engineering Co., Ltd. is a leading provider of drilling solids control equipment and drilling waste treatment solutions. With its global rich and extensive experience, the company has become a trusted partner in more than 60 countries around the world. Their main focus is on drilling waste treatment, solids control equipment, and mud recovery systems, among others.

A major feature of the drilling waste treatment solution of Xi’an KOSUN Environmental Engineering Company is that it includes various technologies such as oily sludge thermal washing treatment system and oily sludge thermal desorption treatment. These innovative approaches ensure the effective removal of hazardous substances from waste, thereby facilitating the adoption of more sustainable waste management methods. In addition, the company also specializes in the treatment of oil-water mixed waste mud and water-based drilling waste, providing comprehensive solutions for different types of drilling waste.

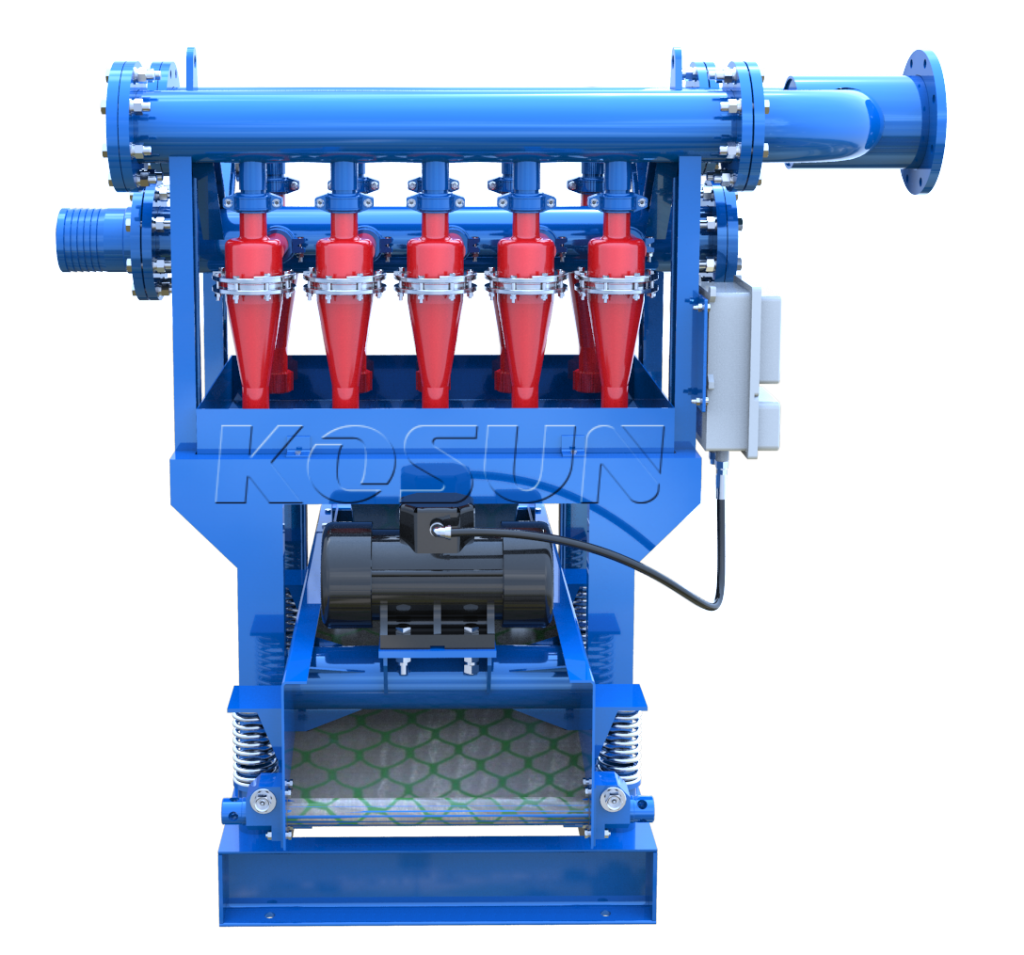

The company’s commitment to environmental protection is reflected in the development of green and environmentally friendly sludge treatment and soil remediation equipment. Xi’an KOSUN combines vibration separation technology, centrifugal separation technology, and fluid mechanics to create an efficient and effective solid-liquid two-phase separation solution in the process of garbage disposal. This can reduce pollutant emissions and recycle reusable resources, meeting local government emission standards and environmental protection requirements.

Xi’an KOSUN recognizes the importance of complying with national policies and regulations. Their focus on providing environmentally friendly solutions meets the growing global demand for sustainable practices. By utilizing drilling waste disposal equipment, companies can contribute to a cleaner environment and minimize their impact on the surrounding ecosystem.

In conclusion, Xi’an KOSUN Environmental Protection Co., Ltd. provides comprehensive drilling waste treatment solutions through its series of drilling waste treatment equipment. With a global presence and commitment to green practices, the company has become a trusted partner to companies in the drilling industry. By leveraging its innovative technologies and expertise, the company can effectively manage drilling waste, reduce emissions and meet environmental regulations. Ensure a sustainable future for your drilling operations by investing in Xi’an KOSUN drilling waste treatment solutions.

Related Link: https://www.kosuneco.com/category-7.html

Tags: drilling waste disposal, drilling waste management, drilling waste treatment

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com