Basic principle and characteristics of the horizontal screw conveyor: horizontal screw conveyor is a rotating screw will be pushed forward and transport along the casing of materials in transmission work, is a new kind of in the bottom of the bin and to break the arch and the uniform feeding, its broken arch performance is strong, for all kinds of powdery and granular materials can achieve broken arch and continuous transmission function, and effectively eliminate different particle size and proportion of mixed material in bending phenomenon occurs in the bunker, thus effectively avoid material wriggle through the earth cabin, and to material status as running water.The horizontal screw conveyor has many features. The screw conveyor is convenient for multi-point loading and unloading. The mixing, stirring and cooling functions can be completed simultaneously in the conveying process.

KOSUN is a professional manufacturer of screw conveyors integrating research, design, production, installation and after-sales service. The company in a responsible attitude to customers, the design and manufacture of products in strict accordance with the testing standards for quality testing. Over the years, with advanced technology, excellent quality, by the majority of customers at home and abroad praise.

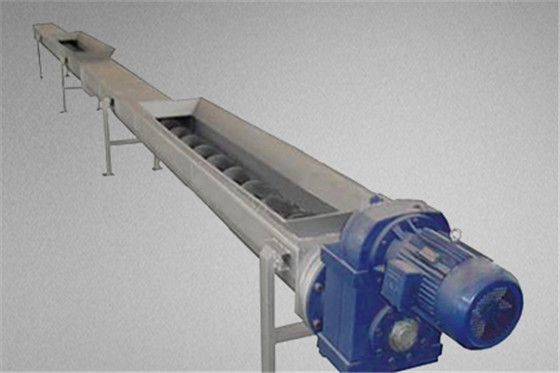

KOSUN screw conveyor is designed in accordance with strict safety standards, and its u-shaped groove has a grille shield to prevent foreign objects from entering the groove, ensuring the safety of the operation of the staff. The bottom frame protects and supports the conveyor, ensuring the structural stability of the equipment.

Features and advantages of KOSUN screw conveyor:

1. High efficiency transmission: compact structure, stepless speed regulation, different processing capacity, can meet the needs of different drilling conditions;

2. Flexibility of the structure: each section is 12 feet and consists of several sections. The total length can be flexibly determined according to the equipment layout at the drilling site;

3. There is a grille cover on the u-shaped groove to prevent foreign bodies from entering the groove, ensuring the operation safety of the staff;

4. The spiral blade of the screw conveyor is made of anti-corrosion and wear-resistant material to extend its service life;

5. Advanced and reasonable design, combined with advanced manufacturing technology and perfect quality assurance system, make it has small volume, large load bearing torque, low noise, oil leakage and other significant advantages.