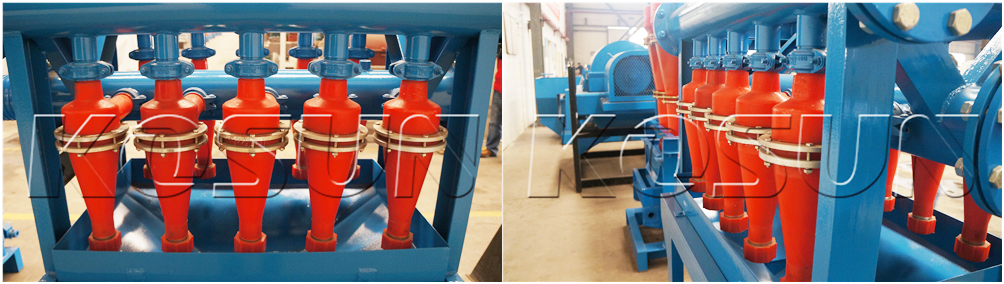

The material of the mud removal cyclone is polyurethane, and the material of the sand settling port is polyurethane + KM wear-resistant coating. The mud removal cyclone is equipped with three specifications of underflow ports: Φ14, Φ18, and Φ22. The appropriate specification should be selected according to different mud conditions. The feed pressure should be controlled between 0.08-0.30 MPa.

The material of the sand removal cyclone is a steel shell lined with rubber, and the material of the sand settling port is high-alumina ceramic. The sand removal cyclone is equipped with three specifications of underflow ports: Φ70, Φ80, and Φ90. The appropriate specification should be selected according to different mud conditions. The feed pressure should be controlled between 0.03-and 0.40 MPa.

Storage precautions for polyurethane cyclones:

The rubber lining components of the cyclone should not be exposed to direct sunlight for a long time during storage because strong ultraviolet rays can cause the aging of these materials. The equipment should be stored indoors as much as possible. If stored outdoors, it should always be covered with tarps or other protective layers.

The equipment should be placed in a safe environment to avoid falling objects or heavy objects, preventing damage to the equipment.

The equipment should be kept away from corrosive liquids or fumes.

The equipment should be kept away from high temperatures, direct flame, and welding.