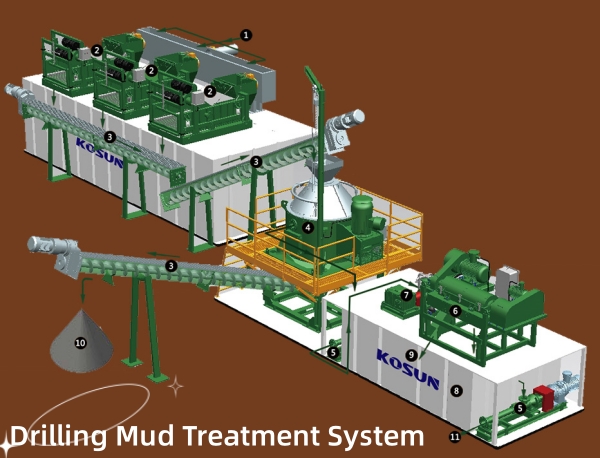

The components and applications of a drilling rig mud tank system may include:

- Mud Tank: It is are large container used to store and circulate drilling fluids (mud) during the drilling process. It has various compartments for different purposes such as mixing, settling, and storing mud.

- Shale Shaker: It is a vibrating screen that separates large solids and cuttings from the drilling mud. It helps in maintaining the consistency and quality of the mud.

- Mud Agitators: These are mechanical devices that stir the drilling mud in the tanks to prevent settling and maintain a uniform mixture. They ensure the mud remains well-mixed and homogeneous.

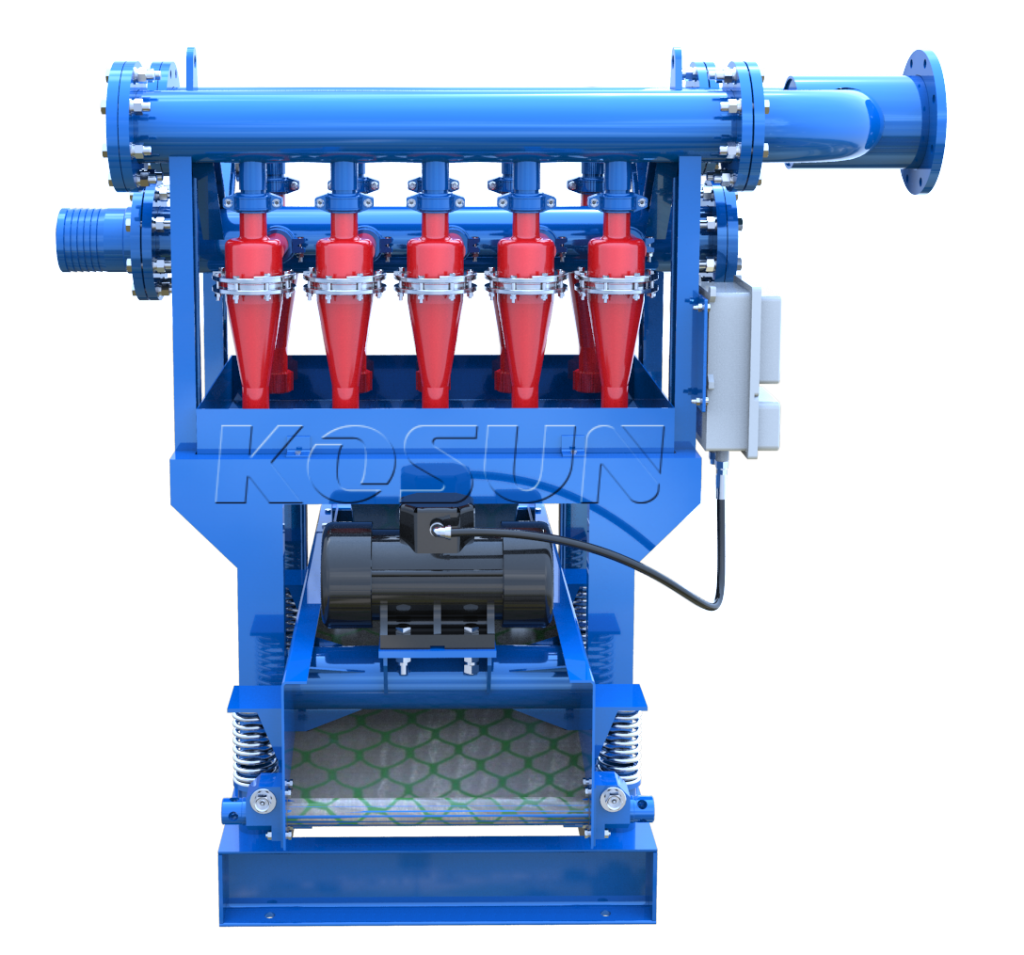

- Desander and Desilter: These are hydrocyclone units used for removing finer solids, sand, silt, etc. from the drilling mud. Desander removes larger particles, while desilter removes smaller particles.

- Centrifuge: It is a machine that uses centrifugal force to separate the components of liquid and solid particles or a mixture of liquid and liquid.

- Mud Pumps: The mud pumps are used to circulate the drilling mud from the mud tanks down the drill string and back up to the surface. They provide the necessary pressure to enable drilling operations.

- Vacuum degasser: The vacuum degasser is usually used to remove gases, such as methane and other harmful vapors, from the drilling mud. It helps in maintaining the safety and stability of the drilling process.

The main applications of a drilling rig mud tank system include:

- Controlling and maintaining the properties of drilling mud, such as viscosity, density, and pH.

- Removing solid particles and cuttings from the drilling mud to ensure proper drilling performance.

- Recycling and reusing the drilling mud to minimize waste and reduce costs.

- Managing and disposing of drilling waste in an environmentally responsible manner.

- Providing a safe and efficient drilling operation by controlling the drilling fluid properties.

Drilling rig mud tank system plays an important role in oil drilling and other industrial fields. It stores, blends, agitates and mixes mud, performs filtration and solid-liquid separation, and controls mud circulation and circulation parameters. The application of a drilling rig mud tank system not only improves the efficiency and safety of drilling operations, but also plays a positive role in environmental protection.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com