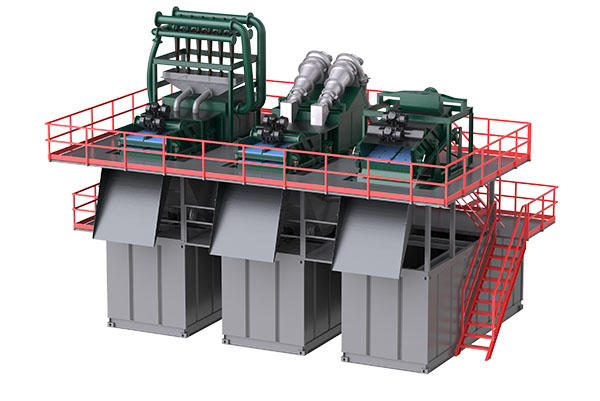

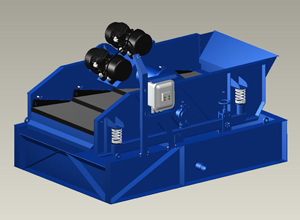

Drilling waste management, mainly with the constant improvement of the environmental protection requirement, puts forward higher requirements on drilling field cutting processing, the emergence of drilling waste purification system, not only can very good to solve the environmental problems, at the same time to the waste of the solid control system to produce secondary recycling, can maximize the retention of mud is useful at the same time, to focus again after processing of drilling cuttings curing processing, reduce the field work for the destruction of the environment. Its main equipment includes: vibrating screen, cuttings dryer, drilling fluid centrifuge, screw conveyor, screw pump and other equipment.

Technical features of KOSUN drilling waste management:

1. Adopt advanced slurry-drying technology, which can effectively recover useful liquid phase in drilling cuttings and achieve high efficiency curing treatment;

2. Low moisture content of useless solid phase after treatment, convenient for transportation;

3. Drilling cuttings drying for oil-based and composite base mud is very effective;

4. Further dewatering and screening the solid particles separated from the first-grade mud treatment to improve the overall treatment effect;

5. Adopt a unique grouting process when dealing with the solid phase of high-flow mud to improve the treatment efficiency;

6. Modular design, convenient and fast moving and transportation;

7. Concealed cable design, well site specification;

8. Simple and practical processing process, small variety of processing equipment, large processing capacity;

9. The whole set of equipment is simple to operate, with less labor and low cost of use and maintenance.