Oil drilling fluid (mud) is mainly composed of four parts: water, active solid phase, inert solid phase and chemical treatment agent. According to the proportion and interaction of each component, different components and different properties of mud can be formed. Therefore, mud composition is the key factor to adjust the performance.

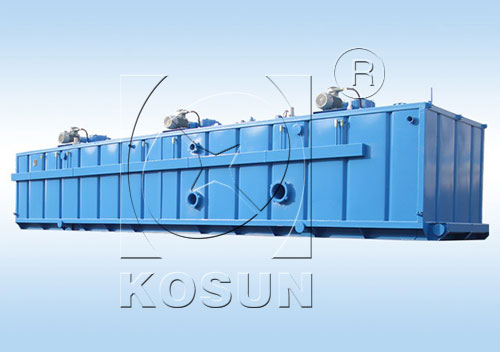

In the preparation and treatment of mud, the traditional preparation method is difficult to achieve the high shear force required for direct hydration of soil and polymer, so it requires a long preparation and treatment time. The SP shear pump developed by KOSUN can quickly prepare high performance mud, greatly shorten the preparation time of mud and improve the economic benefit of drilling.

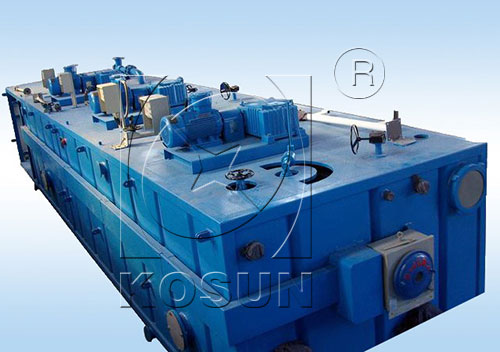

Use and maintenance method of KOSUN SP series shear pump:

1. After each use, circulate the pipeline and shear pump with clean water to avoid debris blocking the flow path and nozzle of the impeller;

2. Check the machine oil level of the oil pool in the support before use. If it is insufficient, it should be replenished.

3 packing box packing and mechanical seal two.When the seal fails, it should be replaced in time.

4. When using the mechanical seal, it is strictly forbidden not to empty the liquid, so as to avoid damage to the mechanical seal. When the lubricating and cooling oil of the mechanical seal is insufficient, it should be timely supplemented.