Drilling operations in industries such as oil and gas, mining, and construction generate a significant amount of waste, commonly known as drilling waste. This waste includes drilling muds, cuttings, produced water, and other substances that are byproducts of the drilling process. Proper drilling waste management is crucial for several reasons, including environmental protection, regulatory compliance, and operational efficiency.

1, Environmental Protection:

One of the primary reasons for proper drilling waste management is environmental protection. Drilling waste contains various substances, including hydrocarbons, heavy metals, and chemicals, which can be harmful to ecosystems if not handled correctly. When drilling waste is not managed properly, it can contaminate soil, surface water, and groundwater, leading to long-term damage to flora, fauna, and aquatic life. By implementing appropriate waste management practices, the potential environmental impacts can be minimized, ensuring the preservation of natural resources and the integrity of the environment.

2, Regulatory Compliance:

Drilling waste management is subject to strict regulations and guidelines imposed by local, regional, and national authorities. Compliance with these regulations is essential for avoiding penalties, legal issues, and reputational damage. Regulatory bodies often require companies to implement specific waste management plans, monitor waste streams, and document disposal methods. By adhering to these regulations, companies demonstrate their commitment to environmental responsibility and ensure the sustainability of their operations.

3, Protection of Human Health:

Improper handling and disposal of drilling waste can pose risks to human health. Contaminated soil, water sources, and air can negatively affect nearby communities and workers in the drilling industry. Exposure to hazardous substances in drilling waste can lead to respiratory problems, skin irritation, and other health issues. Proper waste management practices, such as containment, treatment, and safe disposal methods, help protect the health and well-being of workers and surrounding communities.

4, Operational Efficiency:

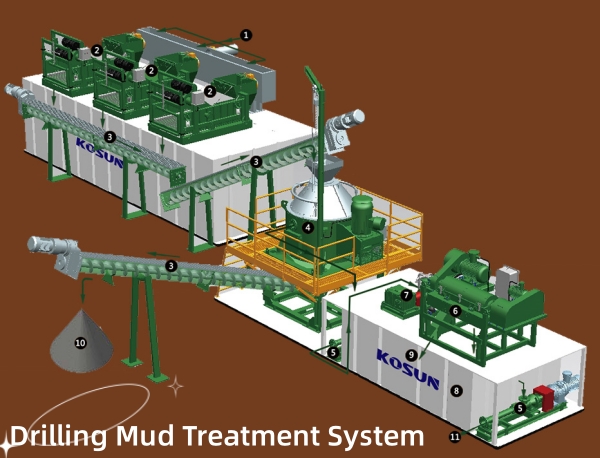

Effective drilling waste management contributes to operational efficiency. When waste is managed properly, it reduces the risk of equipment damage and downtime. For example, solids control systems, such as centrifuges and filtration units, help separate drilling solids from the drilling fluid, extending the life of the fluid and reducing the need for frequent replacements. Efficient waste management also enables the recovery of valuable resources, such as hydrocarbons, which can be recycled or reused, resulting in cost savings for companies.

5, Public Perception and Corporate Social Responsibility:

Proper drilling waste management is vital for maintaining a positive public perception and fulfilling corporate social responsibility. Stakeholders, including investors, customers, and communities, increasingly expect companies to operate in an environmentally responsible manner. Implementing robust waste management practices demonstrates a commitment to sustainable operations and helps build trust with stakeholders. Additionally, companies that prioritize waste management can benefit from the enhanced brand reputation and a competitive edge in the market.

6, Innovation and Resource Recovery:

Proper waste management encourages innovation and resource recovery. Advanced technologies and processes allow for the extraction of valuable resources from drilling waste, such as hydrocarbons, minerals, and water. These resources can be recycled, reused, or sold, providing economic and environmental benefits. Additionally, ongoing research and development in waste management technologies lead to the discovery of more efficient and sustainable methods, contributing to the overall advancement of the industry.

In conclusion, proper drilling waste management is crucial for environmental protection, regulatory compliance, protection of human health, operational efficiency, public perception, and corporate social responsibility. By implementing effective waste management practices, companies can minimize their environmental impact, ensure compliance with regulations, protect the health of workers and communities, optimize operational efficiency, and contribute to sustainable resource management. As the focus on environmental sustainability grows, proper drilling waste management becomes an essential component of responsible and efficient drilling operations.

Tags: drilling waste management, suppliers, manufacturers, factory, wholesale, buy, price, quotation, bulk, for sale, companies, stock, cost.

Related Product:

https://www.kosun.com/products/drilling-waste-management/