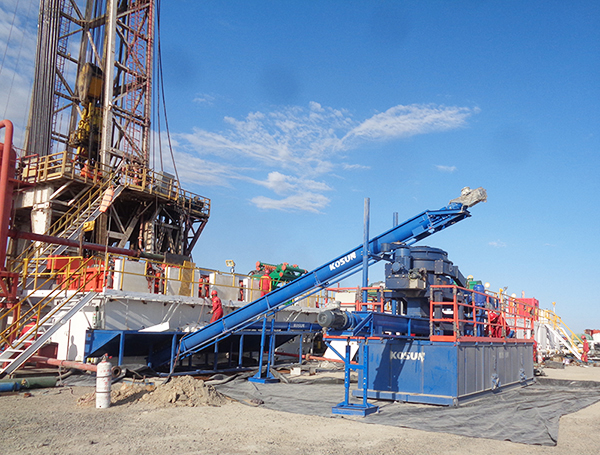

An efficient Tunnel Boring Mud System is the basis for the successful use of slurry-supported tunnel boring machines(TBM). KOSUN Tunnel Boring Mud System is popular for project of AVN Machines, Mix shields or Shaft Sinking Machines and is suitable for purifying slurry in the mud-water balance shield, diaphragm wall, pile foundation and other projects in the process of circulation drilling. KOSUN Tunnel Boring Mud System can save construction costs, reduce mud emissions and reduce environmental pollution. It is an economical, efficient and environment-friendly necessary construction equipment.

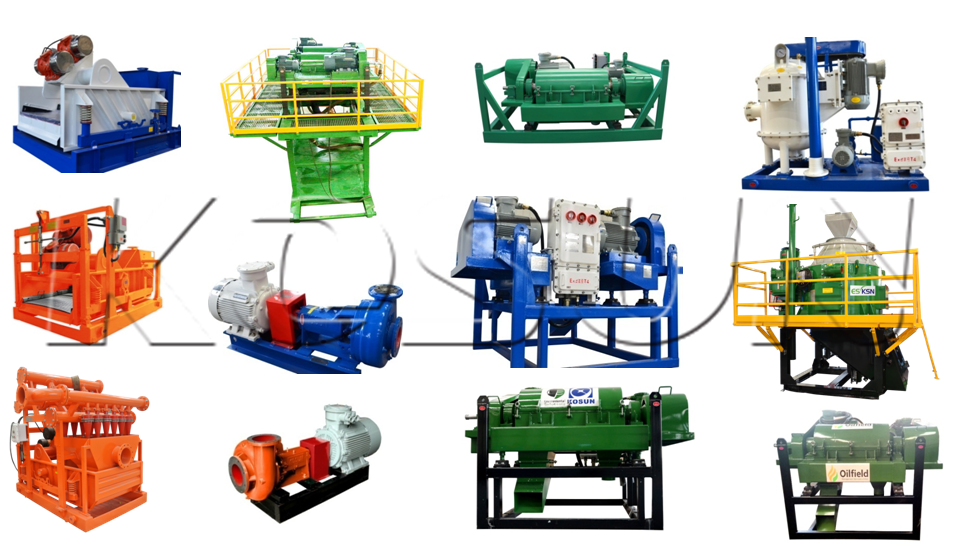

Advantages of Tunnel Boring Mud System:

(1) Simple and useful treatment process, as well as convenient installation, operation and maintenance;

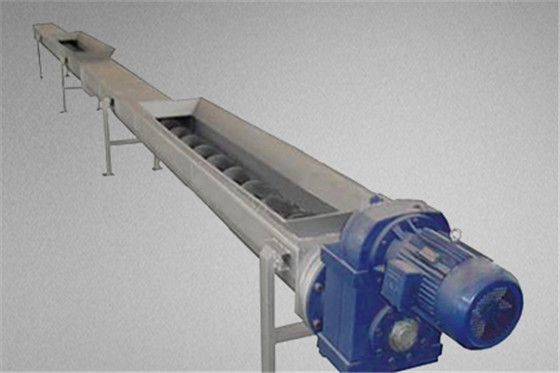

(2) Modular and integrated design, transportation and installation subject to standard container size, foldable operating platform, compact structure, small footprint and flexible field use;

(3) Adjustable G-force of shale shaker, screen panel angle and mesh size, strong overall system adaptability and easier treatment of materials from various formations;

(4) Meet separation requirements on various materials and customize process as per the cut point of D 50 ; meet the requirements on different handling capacities, 100~3000m³/h;

(5) Meet various power specifications as per construction needs, and even generator set can be used for operation;

(6) The whole system is skid-mounted integrated system and can be also changed into vehicle-mounted mobile treatment units.

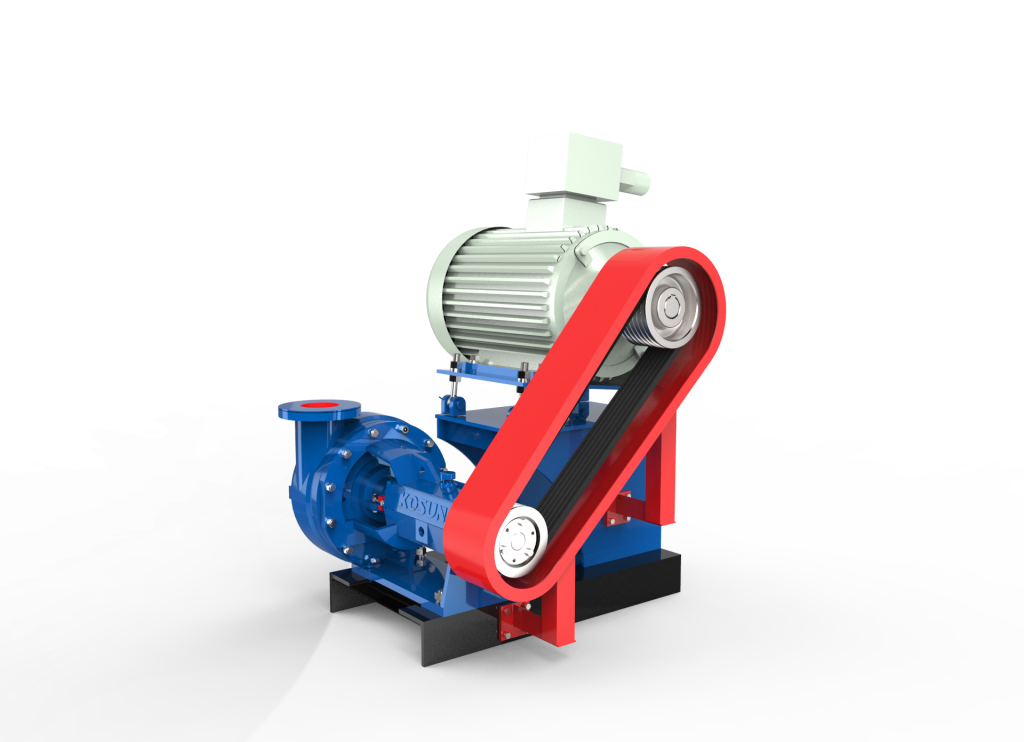

KOSUN Tunnel Boring Mud System utilize our shale shakers, desander, desilter, as well as decanter centrifuges to processes separate and remove the excavated solids from the bentonite suspension – a mixture of water and thixotropic clay. The cleaned fluid is then transferred back to the slurry circulation. Tunnel Boring Mud System is very important for slurry tunnel boring. KOSUN is also very professional at Tunnel Boring Mud System.(Editor:Kosun Lily Wang)

Kosun-China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com