Drilling waste Management

Drilling fluids and cuttings are emitted during drilling. According to the American Petroleum Institute estimates that only 1995, the United States onshore drilling to produce about 150 million bbl drilling waste, so the drilling waste recycling is urgent need nowadays.

In order to minimize drilling waste , the use of environmentally friendly tertiary waste treatment methods:

(1) adjust the drilling process or use the appropriate drilling fluid, so that the waste generated by the drilling process at least;

(2) will have been reduced to Minimum drilling waste is recycled as much as possible; and

(3) Drilling waste treatment that can not be recycled by lawful meant.

1. Use synthetic base drilling fluid

The new synthetic base drilling fluid has the drilling characteristics of oil-based mud, but does not contain polycyclic aromatic hydrocarbons, but also has low toxicity, faster biodegradability and low bioaccumulation. Will not bring great environmental impact to the seabed. Compared with water-based mud, synthetic mud makes the wellbore cleaner and more stable, resulting in fewer cuttings and can be recycled, usually water-based mud cuttings directly into the sea.

2.Drilling fluid recycling

Will be used oil-based mud and water-based mud recycling, to minimize the amount of drilling waste emissions.

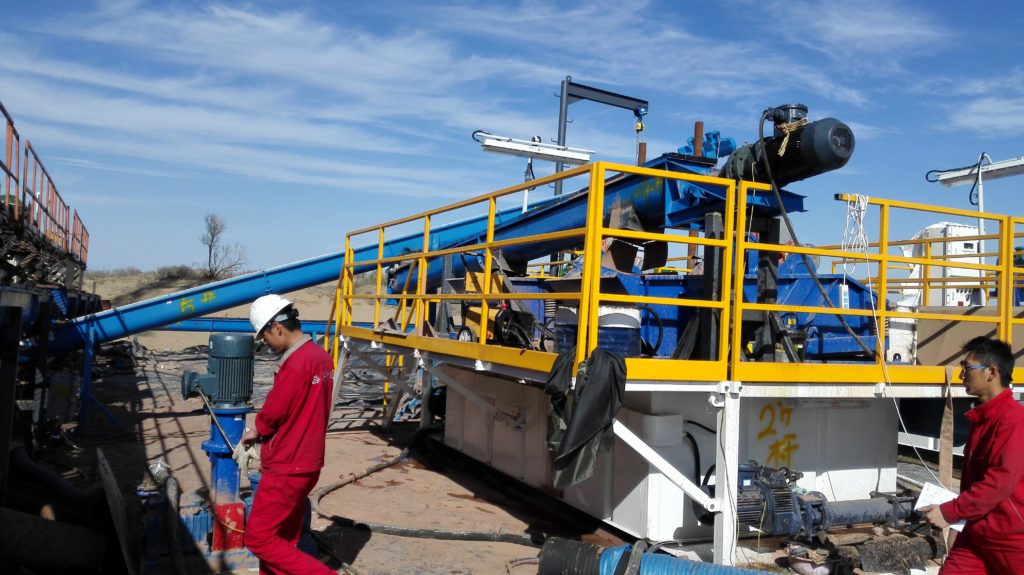

3. Treatment of drilling waste

Conventional land-based drilling waste is treated by first extracting the liquid portion of the slurry pool and then landing or dispersing the remaining solid material in situ. In oil and gas production areas, oilfield waste is dedicated to landfills; other areas will meet the emission standards of drilling waste transported to urban or industrial waste landfill. Another approach is to recycle the waste into the formation through the drilling annulus, including pouring the effluent into the formation fractures at a pressure above the formation fracture pressure or pouring the effluent into the formation at a pressure below the formation fracture pressure Natural cracks and salt holes.

Oil and gas industry has made great progress in environmental protection, there are a variety of drilling waste disposal methods, operators can be in accordance with the relevant legal requirements, cost and environmental requirements to choose the most appropriate drilling dirt treatment methods. New drilling waste disposal methods are being studied to meet future environmental requirements.