Do you know what the important things are for oil drilling fields? Maybe there are two things we should consider, one is how to improve oil drilling work efficiency, and the other one is how to protect the environment around the oil drilling fields. Today KOSUN want to share our ideas about solving the two questions. When we prepare to answer the two questions, we will mention two system: solids control system and drilling waste management.

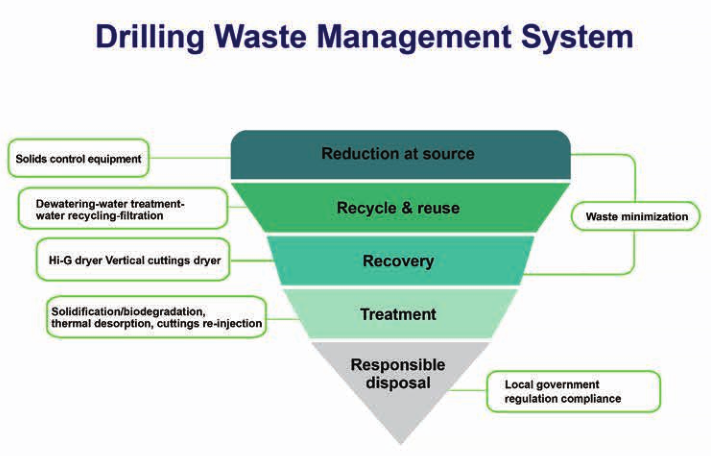

First, how to protect the environment around our oil drilling fields?

-KOSUN drilling waste management.

Just as we know, with the development of society, people have a strong mind about environment protection; we all know the importance of environment-friendly or eco-environment, we all know the importance to balance the economy development and environment protection, which is the same to our oil drilling works.

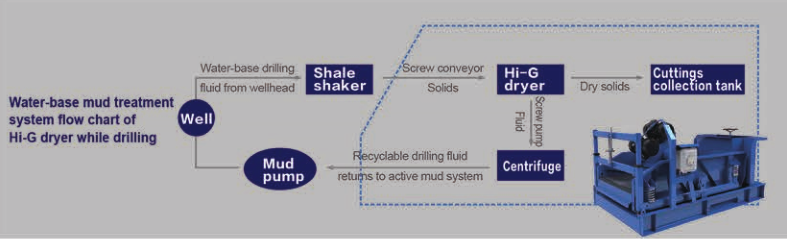

KOSUN have researched and manufactured our latest equipment – vertical cutting dryer, which is the core equipment for our drilling waste management equipment (it is also called drilling cuttings management system). Different models could meet your multiple demands in oil drilling works, especially for environment protection during the oil drilling works.Besides the cutting dryers, there are also some other important equipment for the whole drilling waste management equipment, such as decanter centrifuge, screw pumps, sand pump, screw conveyor, mud tank, etc. the whole solids control equipment could be combated together via new technology, and then provide an amazing working results, such as good environment protection.

Second, how to improve work efficiency in oil drilling works?

Generally speaking, there are many ways to reach this goal, at the same time, with the development of oil drilling fields, more and more new products come into our life and work, high quality and high tech to provide a high efficiency oil drilling works. About this question, KOSUN gives our own answer – Solids Control System.

KOSUN solids control system, which is also called mud system, you can use them in any kind of oil drilling fields. Why I said our solids control system or mud system could solve the problem of work efficiency? The reason is that our solids control system is constituted of high quality solids control equipment, such as mud tank, shale shaker, decanter centrifuge, mud cleaner, shale shaker screen, vacuum degasser, sand pump, etc. Usually, if we just use single solids control equipment, maybe the work efficiency will be lower than our expectation; while if we use newly technology to combine the different solids control equipment together, and test them until working smoothly, we must to say we have reached the goal of improving oil drilling work’s efficiency. That’s why KOSUN Solids Control Systemcould provide you a high work efficiency guarantee.

The above two points are about KOSUN solids control system and drilling waste management equipment, they are two different types system or unit, but they are the same in some extent. You could find the difference between the two systems, while you can also find the similar points between them.

The solids control system/mud system and drilling waste management equipment are the big success for KOSUN, more and more customers and partners choose these two systems used into their overseas oil drilling platforms. Anyway, solids control system and drilling waste management unit are born to improve your oil drilling work efficiency and protect the oil drilling fields environment.

Kosun- China Solids Control Leader&Drilling Waste Mangement Expert