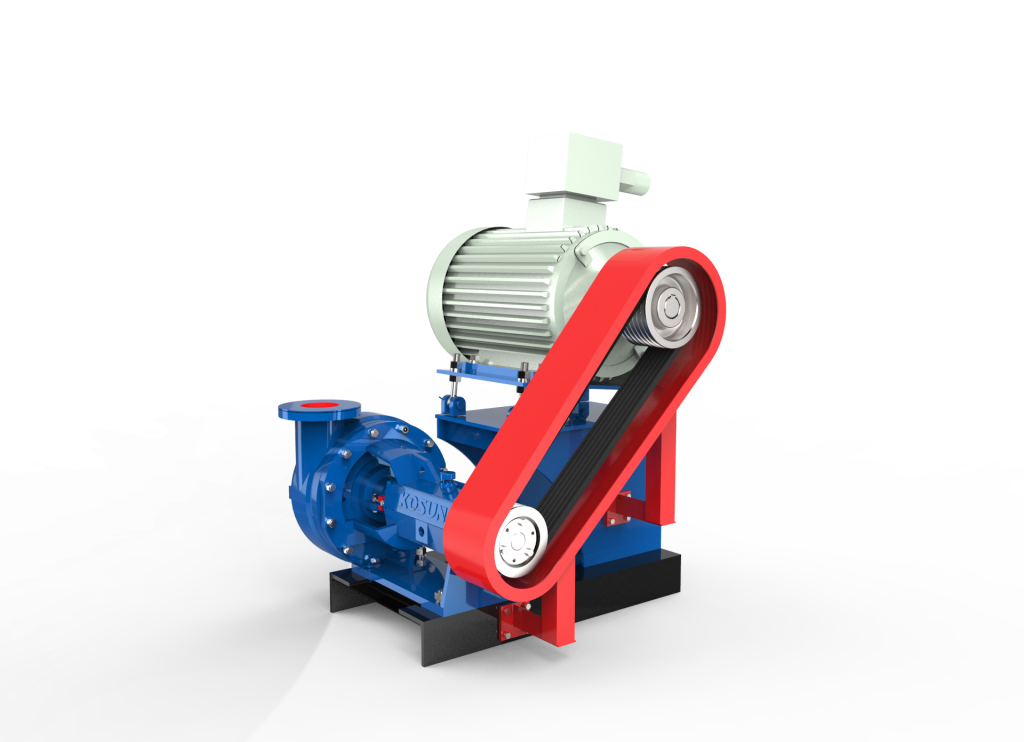

KOSUN SP series shear pump is a centrifugal pump designed for quick configuration of drilling mud.

SP series shear pump can effectively mix and fully hydrate the added materials in the drilling fluid, save the use of mud materials, shorten the mud configuration time, provide good mud performance for the drilling process, is an ideal drilling fluid solid control equipment. The degree of dispersion and hydration of bentonite particles in water depends on: electrolyte content, time, temperature, number and concentration of surface replaceable cations in water. Other things being equal, SP series shear pumps can save bentonite by more than 30%.

SP series shear pumps allow the polymer to be diluted and hydrated as soon as possible. The high molecular weight of the polymer used in the mud is high, and it is not easy to hydrate directly, so the polymer needs to be pre-cut. The shear pump provides high shear efficiency and speeds up the dilution and hydration of the polymer, thus improving the quality and efficiency of the mud distribution.