Drilling Waste Treatment

Drilling waste treatment of pit Less Mud system, is a very important thing that is required to maintain is a proper integration between the drilling waste management system and solid maintaining process.

Oil and gas drilling is one of the most prolific business now a days. A very complex mechanism is used to drill oil and gas from the mine. A very common equipment that is seen in oil and gas drilling area is a shale shaker.

There are two basic approaches of drilling using shale shakers .

The first one is the solid control system which is very popular for drilling now a days.

The second approach is the pit less mud system for drilling. Today the focus will be given on the pit less mud system for drilling.

What is pit less mud system for drilling: The pit less mud system for drilling is basically a process in which no pit is dug on the surface while for collecting cuttings from drilling.

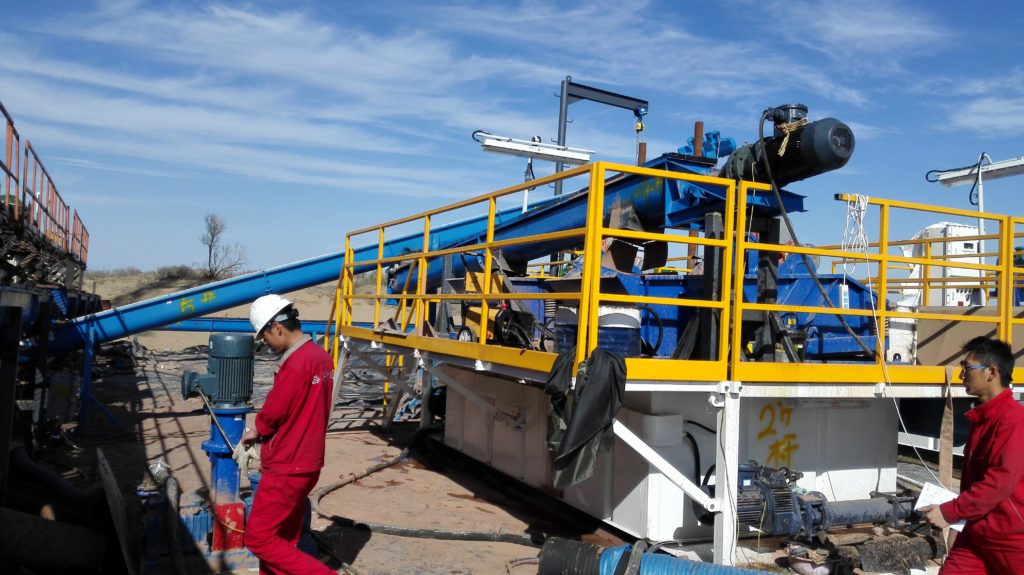

When the drilling waste cuttings are taken out from shell shaker, two particular equipments named G force drying shaker and vertical cutting dryer are used to extract the liquid and to make the cuttings drier. After that, the dry cuttings are transported from the shale shaker unit to the disposal unit. In that stage, the waste cuttings can be disposed on the surface without digging any pit. In many oil and gas drilling sites, a more environment friendly approach is taken to dispose drilling waste cuttings .

In that case, the drilling waste cuttings are taken to another unit for the final processing. In this unit, the waste cuttings are processed via solidification process. Waste cuttings can also be processed by thermal desorption machine. Thus, the drilling waste cuttings become contamination free and environment friendly. Then, the waste cuttings can be disposed without any fear.