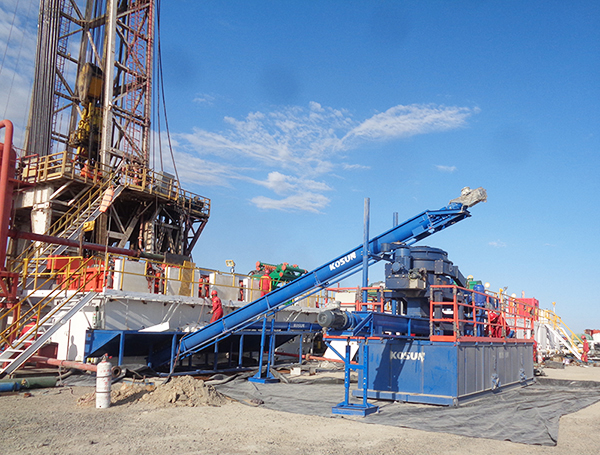

Kosundrilling waste treatment system is also known as drilling mud zero-discharge, rock cuttings mud zero-discharge, drill cuttings mud zero-discharge, mud while drilling mud zero-discharge. According to the useage, it is divided into: water-based mud zero-discharge and oil-based mud zero-discharge. Its main equipment includes: dry shale shaker, drill cuttings dryer, drilling fluid centrifuge, screw conveyor, screw pump, etc. The mud zero-discharge can effectively control the cuttings moisture content (6% -10%) in the drilling mud, stabilize the liquid phase performance, and achieve the purpose of mud zero-discharge drying treatment. According to customer needs and site conditions, the mud zero-discharge system can be customized.

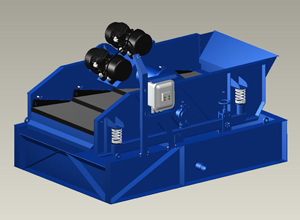

Filter presses and drill cuttings dryers are important equipment for processing drilling mud waste to achieve solid-liquid separation and dehydration and drying. Compared with drill cuttings dryer, the filter press is an early dewatering device for waste drilling mud. It requires the addition of chemical auxiliary, the screen cloth is easy to block, the operation is complicated, the labor intensity is high, and the maintenance cost is high. The drill cuttings dryer is a new type of solid-liquid separation and drying equipment. It does not need to add chemical auxiliary. The

vibrating screen is not easy to block. the installation area is small. It is easy to install and operate. The processing capacity is strong. . With low maintenance costs, at present, it has become an popular equipment for domestic and foreign enterprises to solve the problem of solid-liquid separation and drying of mud in the fields such as drilling while abandoning or abandoned mud ponds, and the treatment of mud zero-discharge .