The decanter centrifuge uses the principle of centrifugal sedimentation to separate the drilling suspension. The suspension enters the drum from the feed pipe through the liquid outlet hole in the screw pusher, and the solid particles are pushed to the inner wall of the drum under the action of centrifugal force and pass through the screw. The blades on the pusher are pushed to the slag discharge port at the small end of the rotating drum, and the liquid phase overflows through the overflow hole at the big end of the rotating drum. Such continuous circulation, in order to achieve the purpose of continuous separation. Sedimentation centrifuges belong to the category of horizontal spiral centrifuges, and the full name is horizontal spiral sedimentation centrifuges. crown

Dewatering principle of the decanter centrifuge: The decanter centrifuge uses the density difference between the solid and liquid phases, and under the action of centrifugal force, accelerates the sedimentation speed of the solid phase particles to achieve solid-liquid separation. The specific separation process is that the sludge and the flocculant liquid are sent into the mixing chamber in the drum through the inlet pipe, where the mixing and flocculation are carried out (if the sludge pump is dosing before the pump or the pipe is behind the pump, the flocculation reaction has been advanced) Due to the high-speed rotation and frictional resistance of the rotor (screw and drum), the sludge is accelerated inside the rotor and forms a cylindrical liquid ring layer (liquid ring area). Under the action of centrifugal force, the solid particles with larger specific gravity settle to the A mud layer (solid ring layer) is formed on the inner wall of the drum, and then the relative speed difference between the spiral and the drum is used to push the solid phase to the cone end of the drum. After pushing out the liquid surface (shore area or drying area), the mud can be dehydrated and dried. It is discharged to the slag discharge port, and the supernatant is discharged from the big end of the drum to achieve solid-liquid separation.

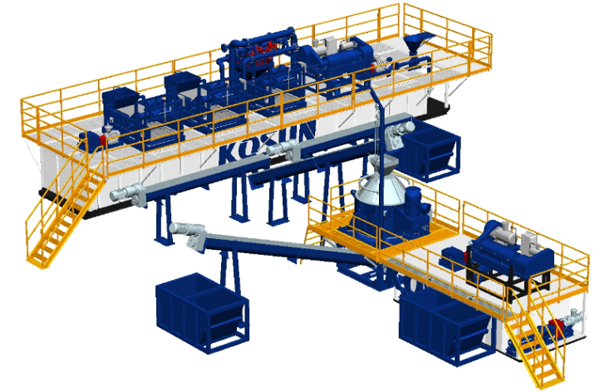

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com