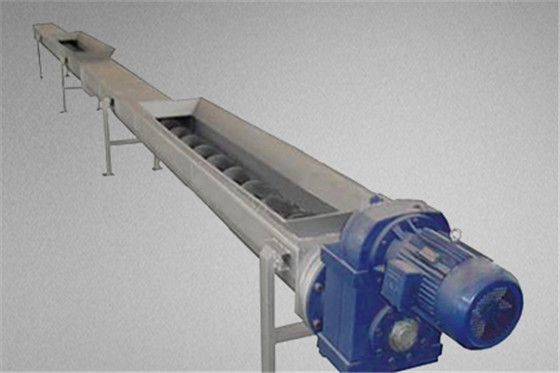

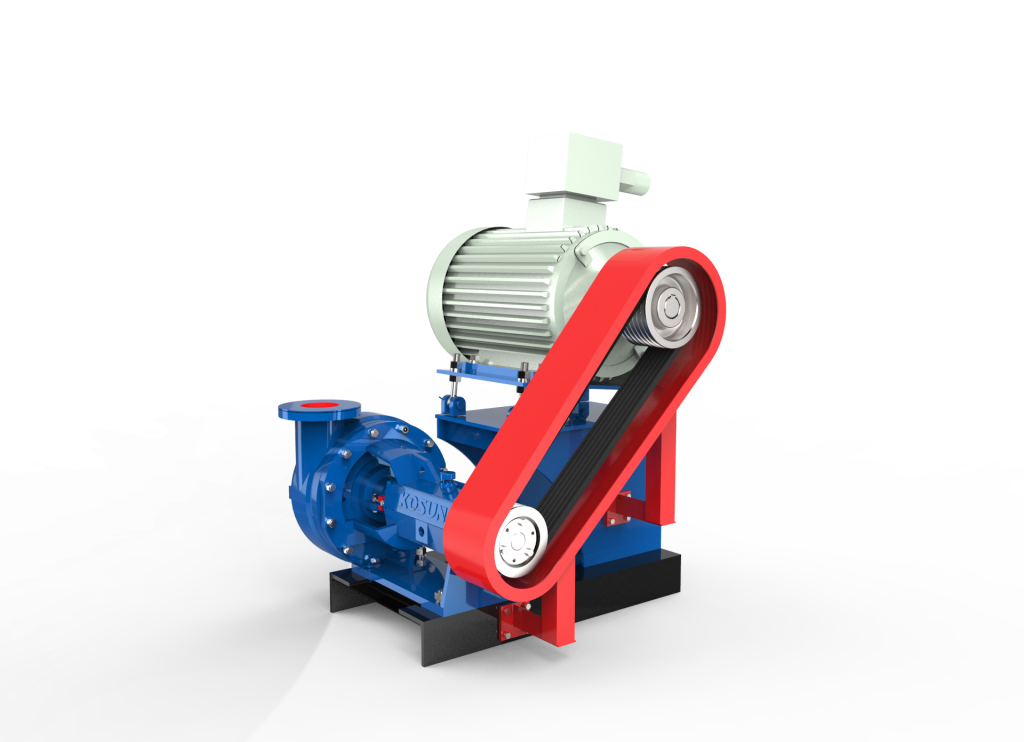

Recently, the 7000-meter orbital drilling rig tank surface solids control equipment produced by KOUSN was sent to the project site in Kazakhstan. This set of solids control equipment includes KOSUN drilling fluid shaker, VD240 vacuum degasser, MD210 mud cleaner, DC450L centrifuge, MA75 And MA55 mud agitator, ignition device, centrifugal pump and other core products.

KOSUN has many orders every year from our old customers. This batch of orders and our customers are the drilling rig suppliers that KOSUN has cooperated with for a long time. For many years, KOSUN has continuously supplied oil and gas drilling solids control equipment to domestic and foreign countries. The quality assurance and customer trust of our products also establish strong confidence for us!

KOSUN solid control equipment is mainly used for solid phase control and solid-liquid separation of drilling fluid in the drilling process. Under the condition of ensuring the stable performance of drilling fluid, the mud can be recycled and reused. KOSUN solid control equipment is equipped with 5-level solid control and dispensing, weighting and other equipment, suitable for drilling projects of 500-9000 meters, and can meet the matching needs of drilling rigs from 250HP to 3000HP.

KOSUN is a professional manufacturer of mud solids control equipment and drilling waste treatment system integrating product development, production and sales. Products are widely used in oil and natural gas drilling, coalbed methane drilling, geothermal drilling, trenchless horizontal directional crossing, pipe jacking, shield tunneling, piling and other projects, tailings treatment, river dredging and other fields. If you want to know more information, welcome to inquire!